the Nottingham Asphalt Tester (NAT)NATs are used by national and regional laboratories, universities, oil companies, contractors and consulting engineers worldwide. Trials have demonstrated that NAT tests give excellent correlation with other test methods such as bending beam and wheel tracking.

APPLICATIONS

The NAT can be used for:-

SOFTWARE

The NAT can be used to carry out the following range of tests:

Test method numbers:

CEN PrEN 13108/12697-26 CEN PrEN 13108/12697-25 CEN PrEN 13108/12697-24

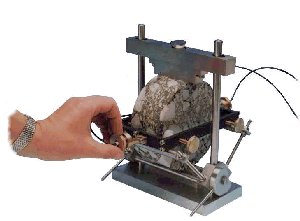

FEATURES   SPECIFICATION FOR AN ASPHALT TESTING MACHINEThe apparatus shall consist of the following:A load frame fitted with a pneumatic actuator and load transducer and capable of applying vertical loads in the range 0 to 4.3kN. An indirect tensile subframe, alignment jig, LVDT yokes, LVDT deformation transducers and software necessary to carry out Indirect Tensile Stiffness Modulus (ITSM) tests on both 10Omm and 150mm diameter cores or moulded cylindrical specimens. A 150mm or 10Omm diameter (customer to specify) PVC specimen for routine checking of (ITSM) transducer accuracy. Hardened, ground and polished platens, LVDT deformation transducers, LVDT mounts and software necessary to carry out both Static Creep and Repeated Load Axial tests on both 100mm and 150mm diameter specimens. A unit for the conditioning and regulation of the pressurized air supply. An electronic interface unit, high resolution, high speed 16 bit multifunction card and parallel link through which all data acquisition and control tasks are carried out by the host computer. The interface unit shall contain all necessary power supplies and signal conditioning for a load transducer, two thermocouples and two deformation transducers with the capability of expansion for up to three additional transducers (ie. up to eight transducers). The data acquisition and control system shall be capable of direct memory access (DMA) for rapid data transfer during tests where timing is critical. The software shall run under Windows 3.1195 to provide a "user friendly" means of carrying out testing using menus, graphical displays and help screens to provide a step by step method of enabling the operator to obtain repeatable and reproducible results. The host computer shall automatically carry out the test and calculate the results. The operator shall have the option of storing the test data on disk and for printing it out when the test is completed. The stored data shall be in a format which can be readily imported into all popular spreadsheets (eg. LOTUS 123 or EXCEL etc.) for subsequent analysis and comparison. A temperature controlled cabinet shall be provided which is capable of controlling temperature in the range -10 to +60� C with temperature fluctuation of �0.2�C and temperature variation of 0.5�C. The apparatus shall be capable of carrying out the following tests: The apparatus shall be equipped with a minimum of a 386SX IBM (or compatible) PC with 3.5inches-xl.44 MB floppy, 1 OOMB hard drive, 1 MB RAM (at least 4 MB RAM for Windows software) and SVGA graphics. An inkjet printer is suitable for routine printouts. The apparatus shall be supplied with pressurized air at 7bar and better than 6cfm. References: |